Series Connected LED Aluminum Purification Lights are designed for cleanrooms and controlled environments that require continuous, uniform illumination. With seamless series wiring, sealed aluminum housing, and high efficiency LEDs, they are ideal for large-scale industrial, pharmaceutical, and laboratory projects.

In modern cleanroom and controlled-environment projects, lighting systems must meet far more than basic illumination needs. They must support hygiene standards, installation efficiency, long-term reliability, and uniform light output.

The Series Connected LED Aluminum Purification Light is specifically engineered to meet these requirements, making it a preferred solution for large-scale cleanroom and industrial applications.

This article explains how series-connected purification lighting works, why aluminum housing matters, and where this lighting system delivers the greatest value.

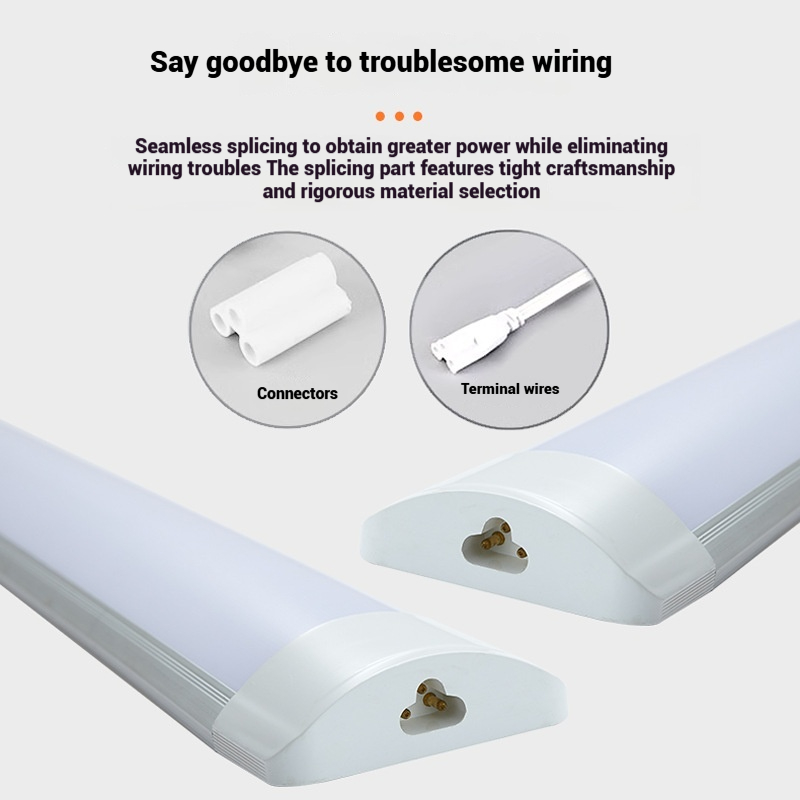

A Series Connected LED Aluminum Purification Light is a sealed LED fixture designed to be electrically connected in series, allowing multiple units to operate through a continuous wiring system. Unlike independent fixtures, series-connected lights reduce wiring complexity while maintaining stable illumination across long installation runs.

Key characteristics include:

Continuous series wiring design

Sealed aluminum housing for hygiene

High luminous efficiency LED modules

Compatibility with cleanroom standards

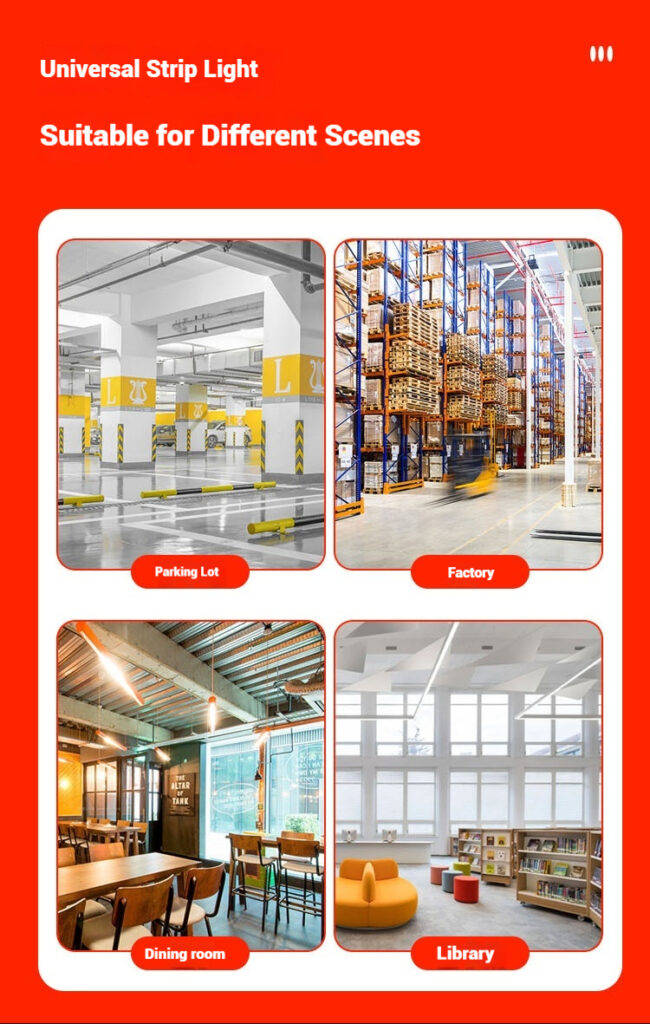

This design is especially effective in long corridors, production lines, and large cleanroom ceilings.

Traditional individual lighting installations require separate power connections for each fixture. In contrast, series-connected systems allow multiple lights to be linked together, significantly reducing:

Cable quantity

Installation time

Risk of wiring errors

This is particularly valuable in large cleanroom projects where hundreds of fixtures may be installed.

Series connection simplifies layout planning and speeds up installation. Contractors can complete projects faster while maintaining consistent electrical performance across all fixtures.

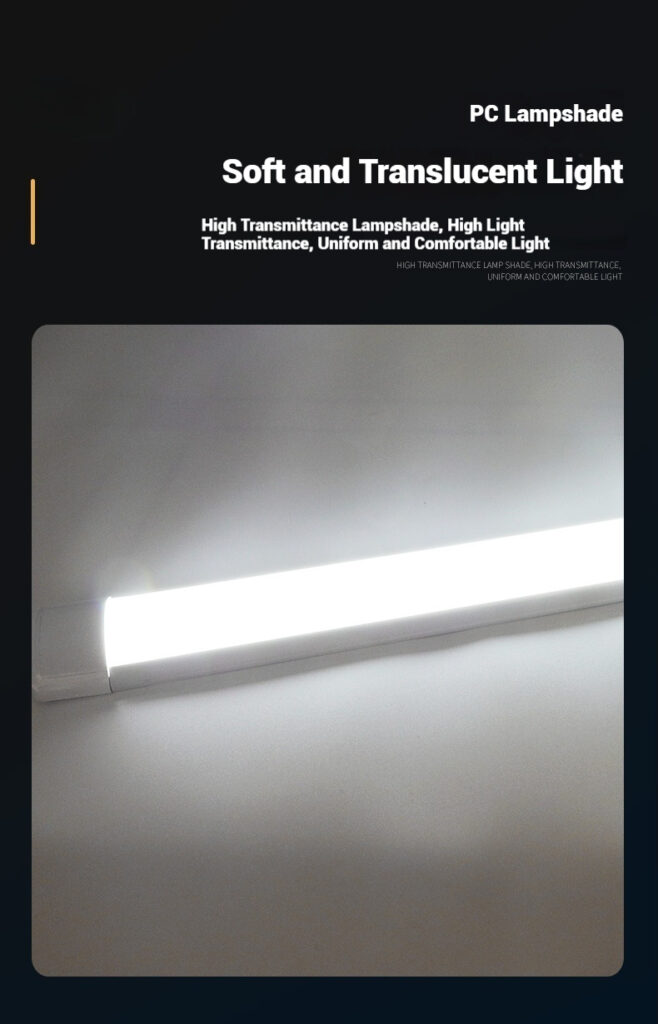

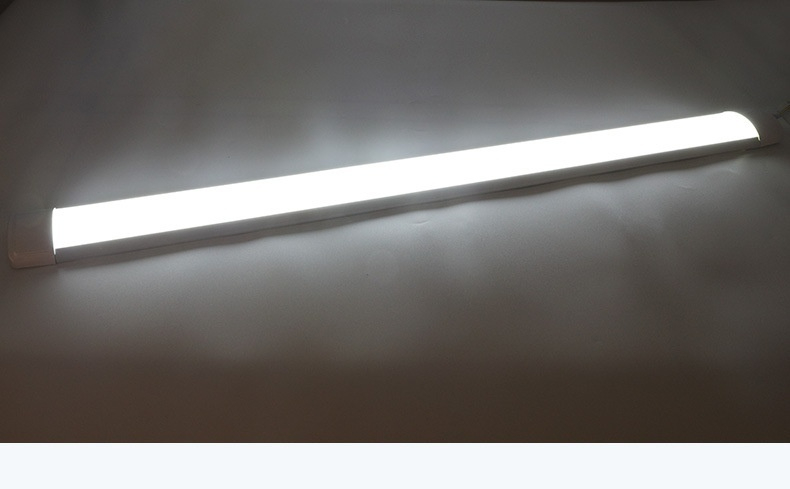

Series-connected LED purification lights are designed to ensure consistent brightness and color temperature throughout the system, avoiding visible light variations that can affect inspection tasks and visual comfort.

Aluminum housings provide a smooth, corrosion-resistant surface that does not easily trap dust or particles. This is critical in environments requiring frequent cleaning and sterilization.

Compared to plastic or steel alternatives, aluminum offers:

High strength with lower weight

Resistance to deformation

Long service life in industrial environments

Aluminum acts as an effective heat sink, helping LED chips dissipate heat efficiently. This improves:

LED lifespan

Lumen maintenance

Overall system stability

Series Connected LED Aluminum Purification Lights are commonly designed to meet cleanroom requirements such as:

Sealed structure to prevent particle leakage

Dust-resistant and easy-to-clean surfaces

Compatibility with airflow systems

Their streamlined construction supports ISO cleanroom environments, pharmaceutical production zones, and electronics manufacturing facilities.

In pharmaceutical plants, consistent lighting is critical for inspection, packaging, and compliance. Series-connected systems ensure uninterrupted illumination across long production lines.

Electronics manufacturing demands stable, glare-free lighting for precision work. Series-connected purification lights provide uniform brightness without disrupting airflow.

Hygiene-focused food facilities benefit from sealed aluminum lighting fixtures that resist contamination and simplify maintenance.

Laboratories require both visual accuracy and clean environments. Series-connected systems reduce ceiling clutter and enhance overall workspace organization.

Series-connected lighting systems can be extended or reconfigured with minimal disruption, making them ideal for facilities planning future expansion.

With standardized fixtures and wiring, maintenance teams can quickly replace or service units without redesigning the electrical layout.

Stable electrical connections and durable aluminum construction help minimize failures, reducing downtime in critical operations.

Series Connected LED Aluminum Purification Lights are designed for high luminous efficacy, helping facilities reduce energy consumption while maintaining required brightness levels.

Benefits include:

Lower electricity costs

Reduced heat generation

Long service life with fewer replacements

Over time, these advantages contribute to a lower total cost of ownership for large-scale projects.

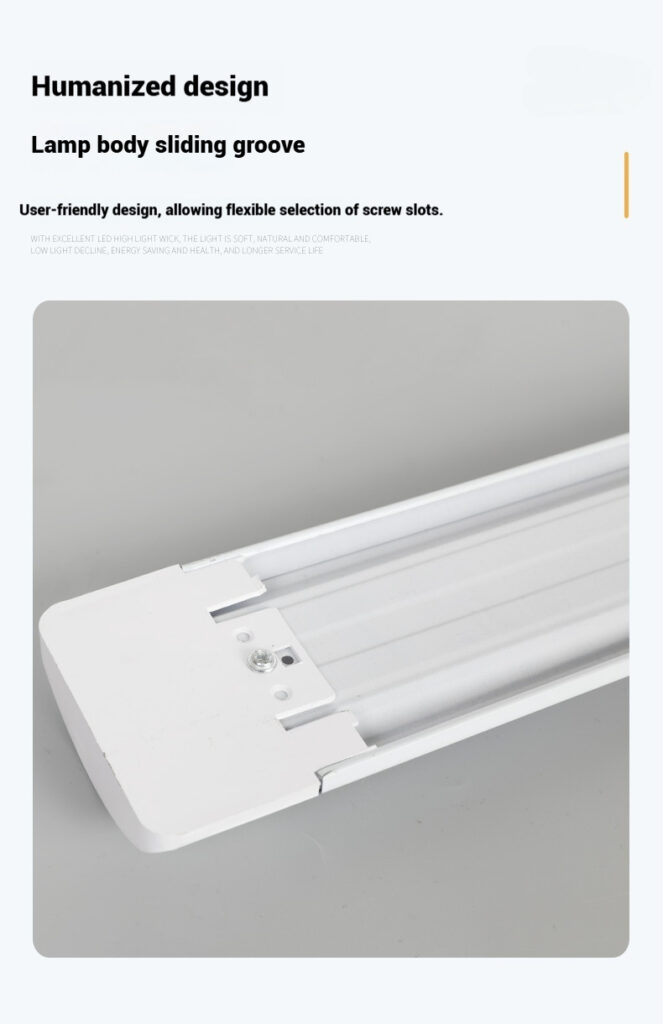

Series-connected systems allow flexible layout options:

Linear arrangements for corridors

Continuous ceiling rows for production areas

Modular grouping for zoned lighting

This adaptability makes them suitable for both new construction and retrofit projects.

When selecting a series-connected LED aluminum purification light, consider:

Cleanroom classification level

Required illumination intensity

Ceiling structure and layout

Maintenance access needs

Project scalability

Working with an experienced supplier ensures the lighting solution meets both technical and regulatory requirements.

For contractors, engineers, and project managers, these lights offer:

Faster installation

Reliable long-term performance

Cleanroom-compliant construction

Professional, organized ceiling appearance

They are a practical choice for projects where efficiency and hygiene are equally important.

The Series Connected LED Aluminum Purification Light is a smart, scalable lighting solution for modern cleanrooms and industrial facilities. By combining efficient series wiring, durable aluminum housing, and hygienic design, it meets the demands of large projects while supporting long-term operational efficiency.

For businesses focused on cleanroom performance, installation efficiency, and future expansion, series-connected purification lighting is a strategic investment.

We also post the blog.“What Is a Series Connected LED Aluminum Purification Light?”

| Size | Width | Power | material | LED chip | Voltage | Color tempreture | RA |

| 0.6M | W73mm | 18W | Aluminum+PC | 2835 | 165-265V | 3000K/4000K/6500K/10000K | 70 |

| 1.2m | W63mm | 36W | Aluminum+PC | 2835 | 165-265V | 3000K/4000K/6500K/10000K | 70 |

| If you have any other requirement or customized, can contact us. | |||||||

About Promaxledlight

Located in Zhongshan City — the lighting capital of China — our company has been deeply involved in the lighting industry for more than 10 years. We specialize in commercial lighting products, including LED honeycomb hexagons lights, LED linear lights, panel lights, LED bulbs, LED office light, LED tube,LED housings bracket and so on.

With advanced production facilities and an experienced R&D team, we are committed to delivering high-quality, energy-efficient, and innovative lighting solutions that meet the diverse needs of customers around the world. Our products are exported to Southeast Asia, the Middle East, and European countries, earning an excellent reputation for reliability and design.

Guided by our core values of quality, integrity, and innovation, we aim to illuminate every space and build lasting partnerships with our global clients.

Our website is www.promaxledlight.com, welcome to visit.

If you want know more about led, can check wikipedia.

Simple FAQ

It means multiple LED fixtures are electrically linked in a continuous circuit, allowing simplified wiring and uniform operation.

Yes. They are designed with sealed structures and aluminum housings suitable for cleanroom and controlled environments.

Many manufacturers offer options for length, power, color temperature, and mounting method to suit specific projects.

Yes. Series-connected systems are often used in retrofits due to their flexible installation and reduced wiring needs.

With proper thermal management and quality components, they typically offer long service life and stable lumen output.